Material

Introduction

In this section, we’ll take a look at some of the most common materials used in the construction of backpacks, messenger bags, laptop bags, and satchels.

There are many types of materials you can use to make a bag, but for this course, we’re going to focus on just a few that are especially common and practical for beginners. If you’re interested in exploring other materials beyond what we cover here, there are plenty of great resources available online to help you dive deeper.

Fabric Basics

Fabric Units

In the United States, fabric is typically identified by its weight per square yard. For example, a 36-inch by 36-inch piece of 10-ounce fabric weighs 10 ounces. A 20-ounce fabric would be approximately twice as thick and heavy as a 10-ounce fabric, assuming the same type of material.

Another important note: when fabric is sold in the U.S., it is typically sold by the running yard. Purchasing a running yard means you're buying 36 inches in length of fabric, regardless of the fabric roll's width—usually between 36 and 62 inches wide.

For example, if you purchase 3 running yards of fabric that is 60 inches wide, you will receive a piece of fabric that is 108 inches (3 x 36) long by 60 inches wide. This is the standard way fabric is sold, but be sure to read the product description carefully to understand exactly what you're getting.

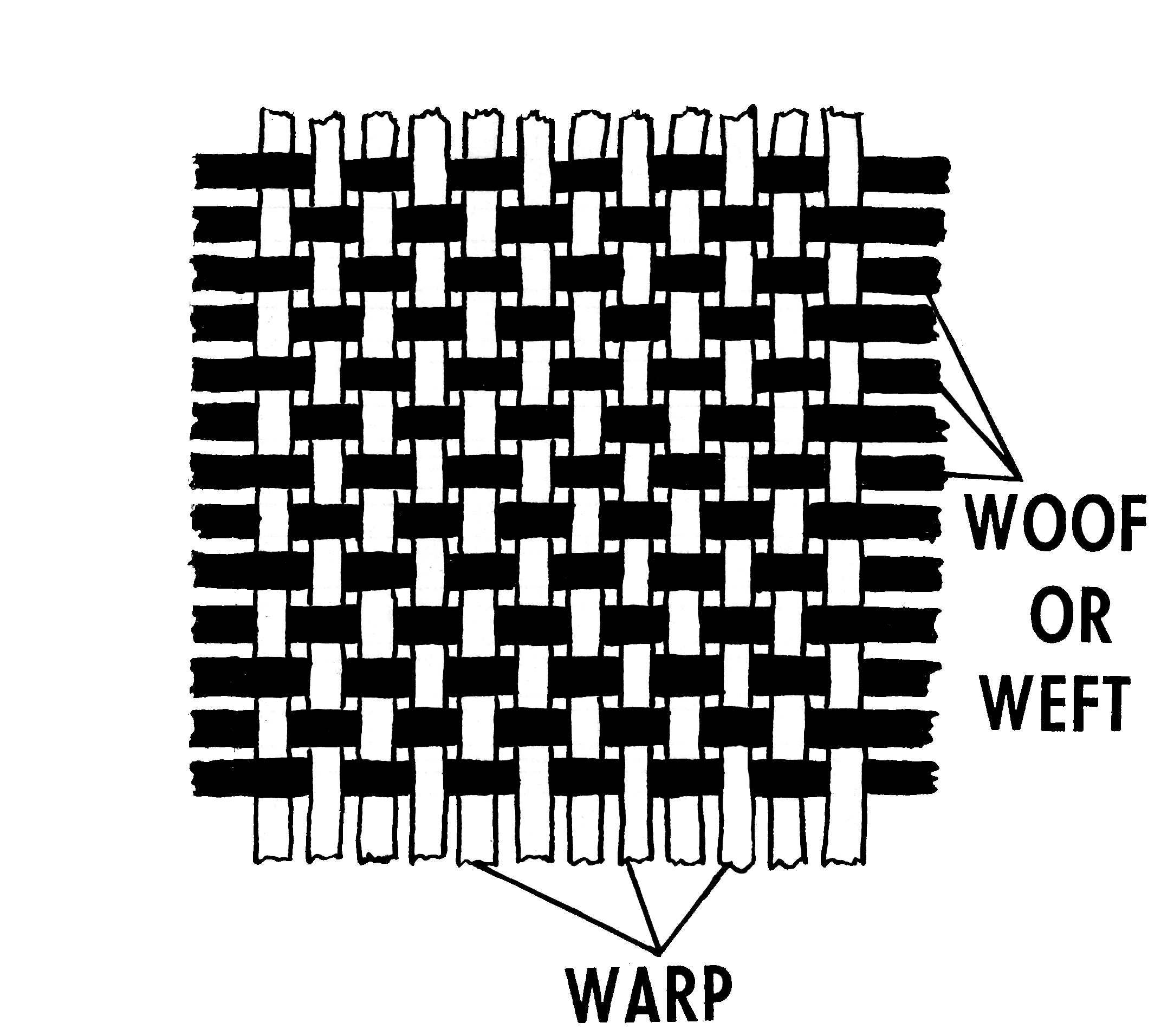

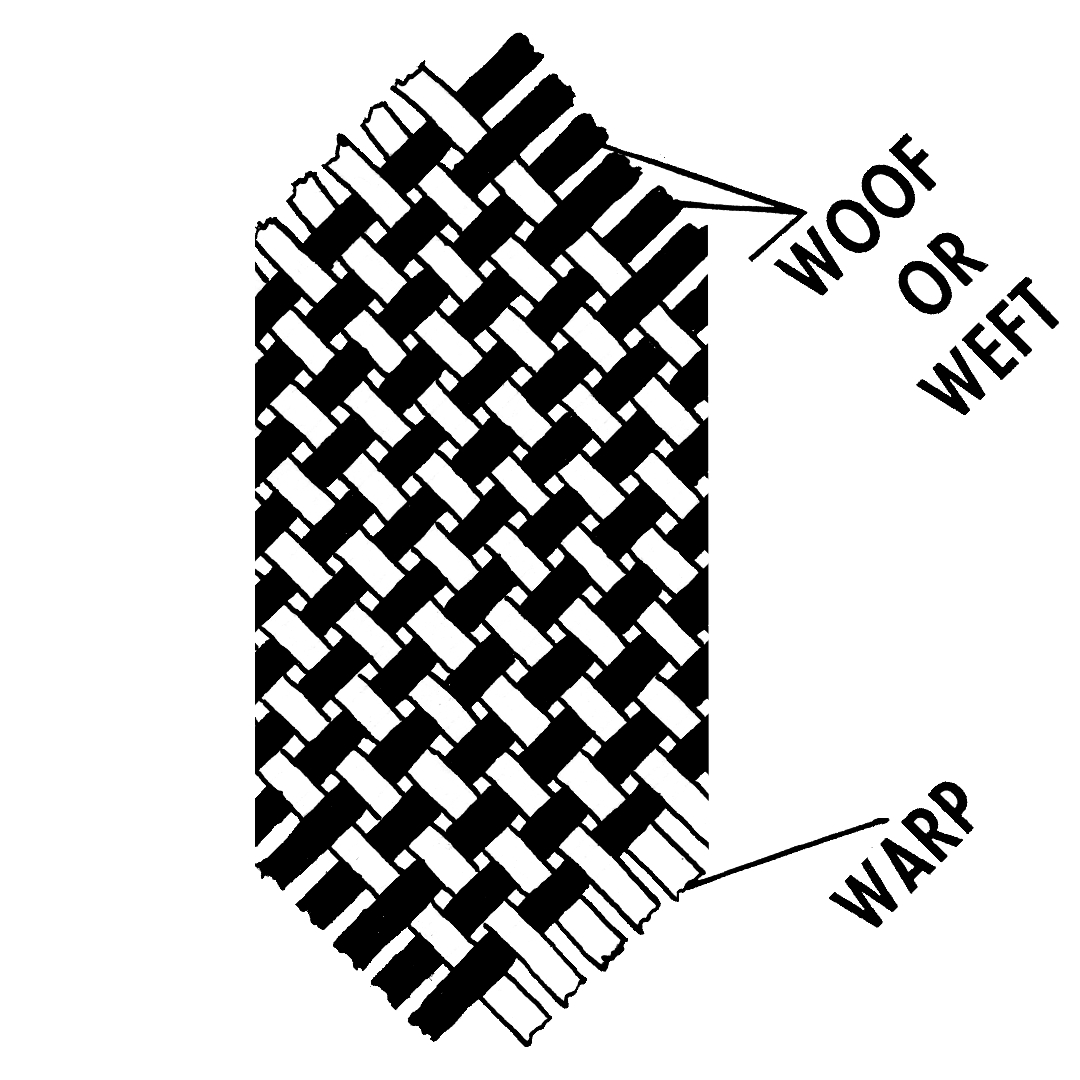

Warp and Weft

When fabric is woven, the fibers running lengthwise are called the warp, while the ones that run side to side are known as the weft. This basic structure forms the foundation of most woven fabrics.

Cotton Fabrics

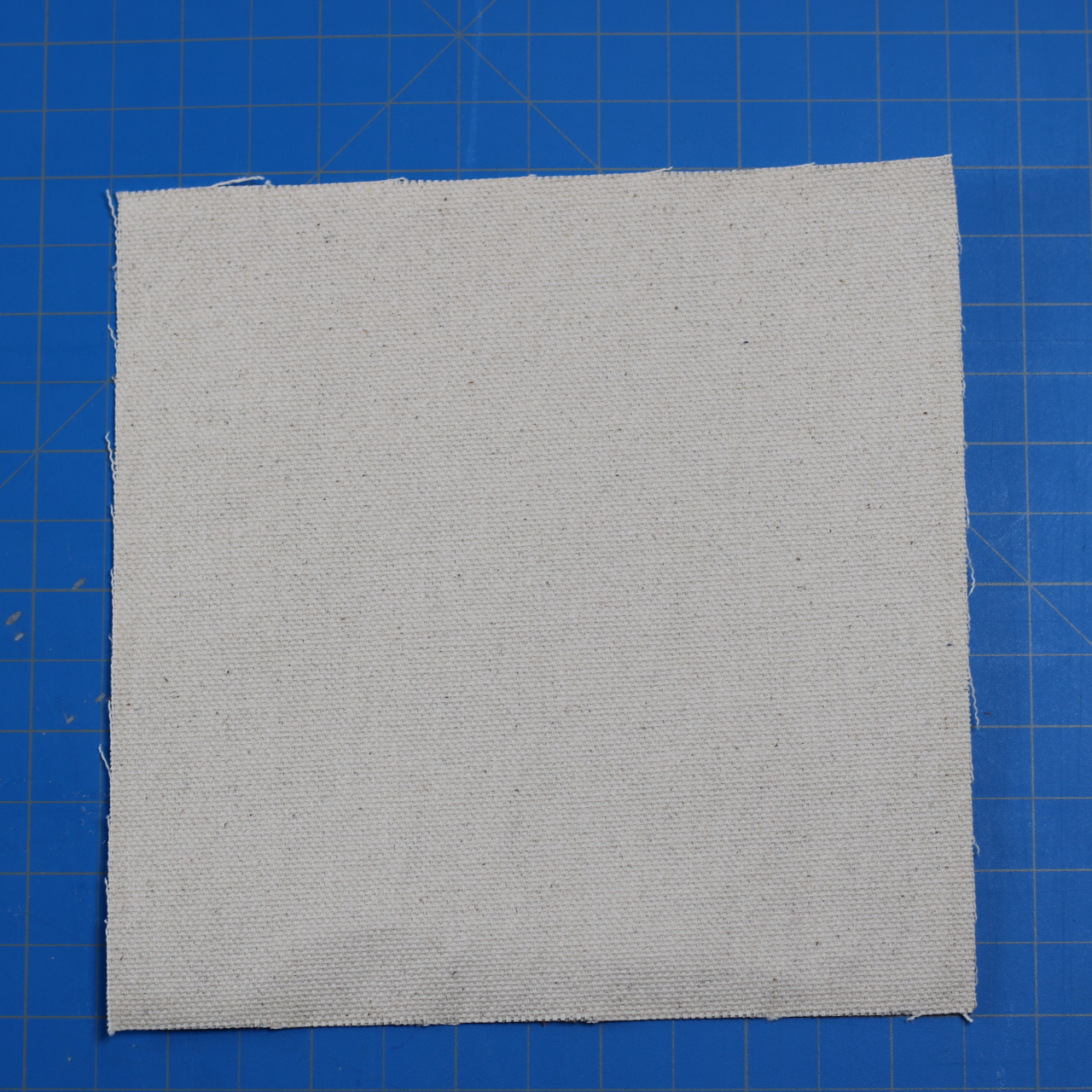

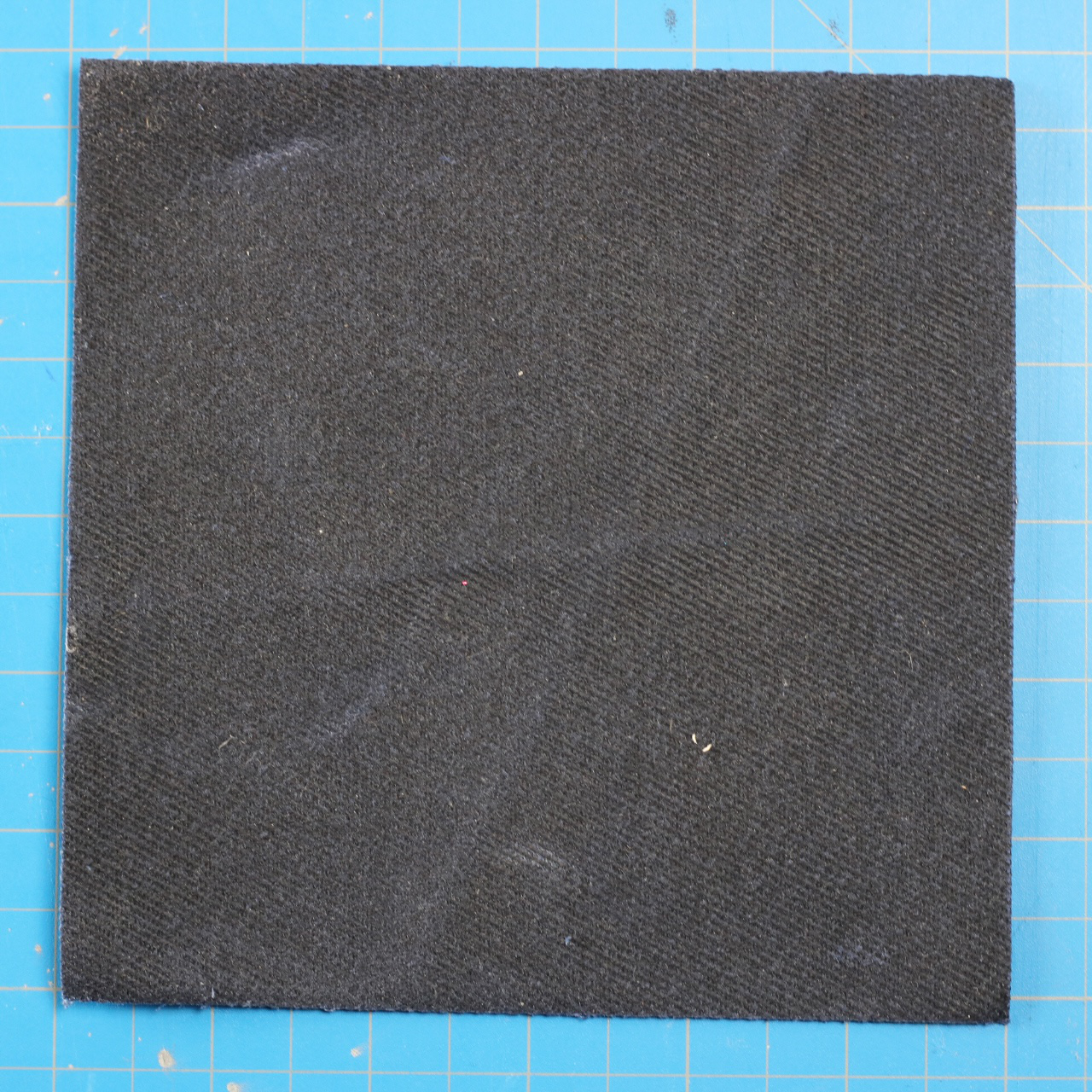

Canvas

Here’s an example of a fairly coarse 10-ounce cotton canvas. You can clearly see the weave in this material. One thing to keep in mind with a coarser weave like this is that it tends to unravel more easily, which can be a challenge when cutting and sewing.

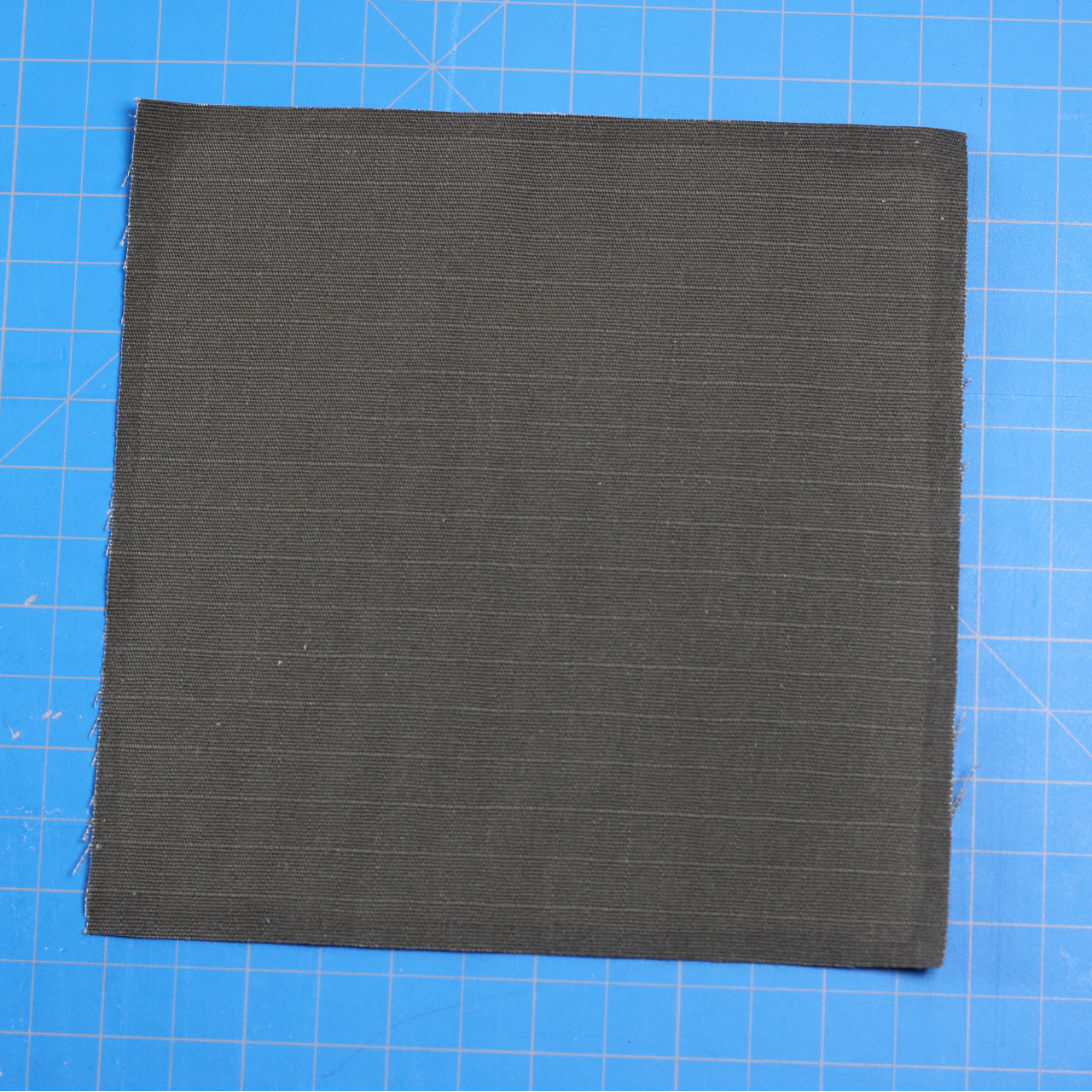

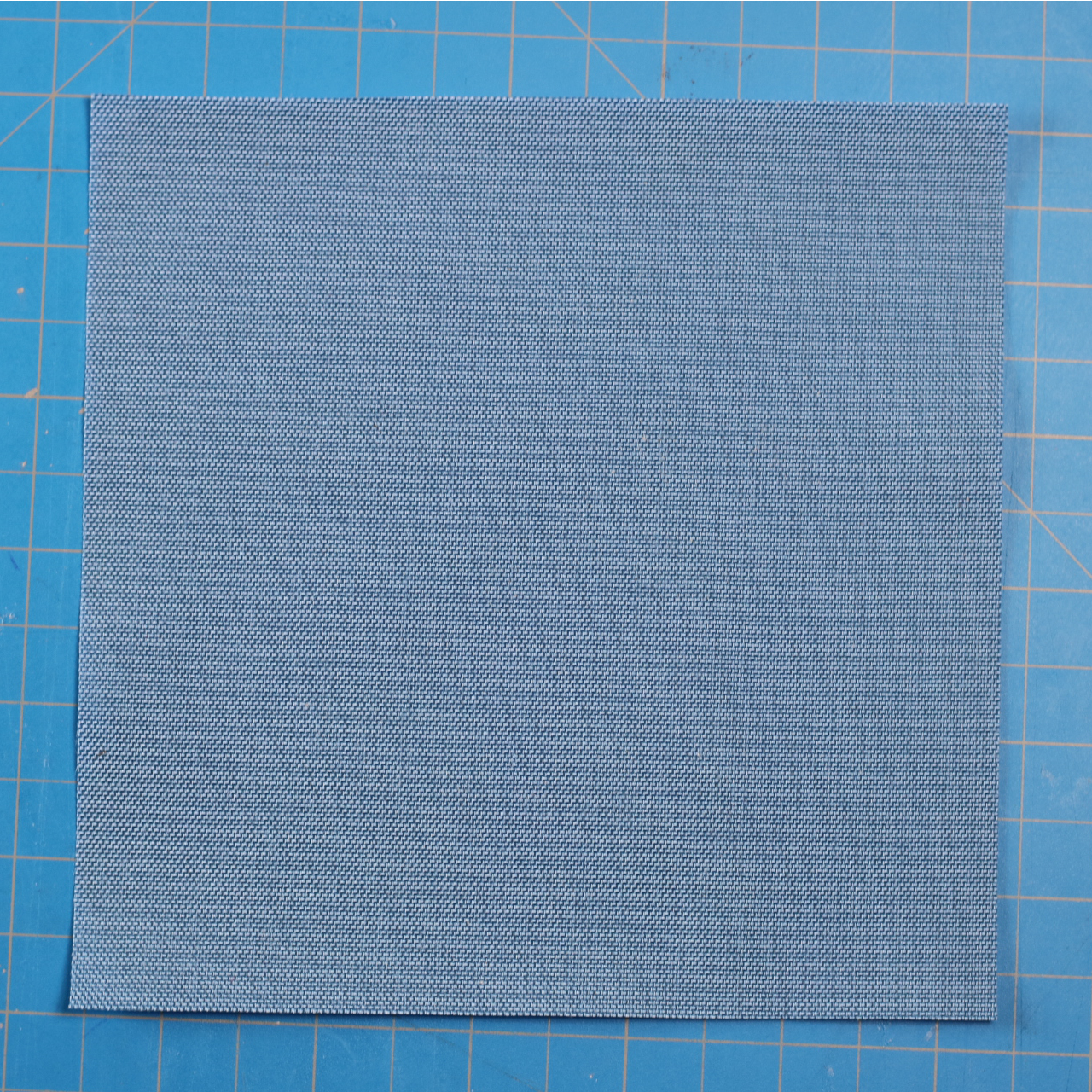

Cotton Ripstop

Compared to standard canvas, ripstop cotton has a much tighter, finer weave. If you look closely, you’ll notice a visible grid pattern. This grid is created by reinforcing the weave with stronger threads at regular intervals. It’s designed to prevent small rips from spreading, making the fabric more durable.

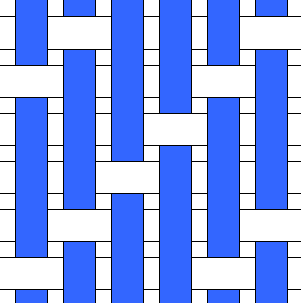

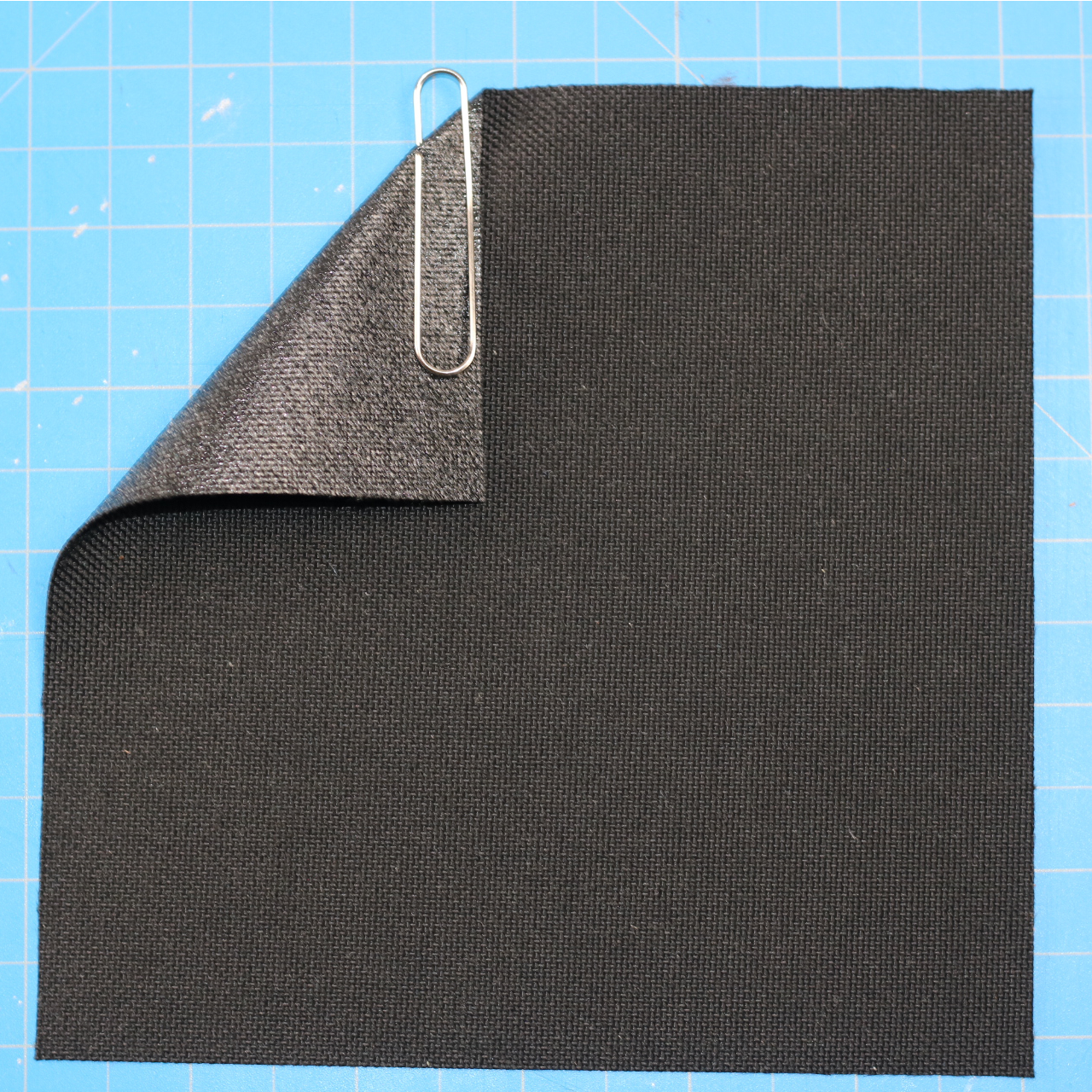

Denim

Denim is another cotton-based fabric, but the way it’s woven is quite different. Instead of a basic over-and-under pattern, the weft threads pass under two or more warp threads, which creates what’s known as a twill weave. This weave gives denim its signature diagonal texture.

In most blue denim, the warp threads are dyed blue while the weft threads are left white. That’s why the outer side appears blue and the inside has a whitish color. It’s all a result of the weaving process.

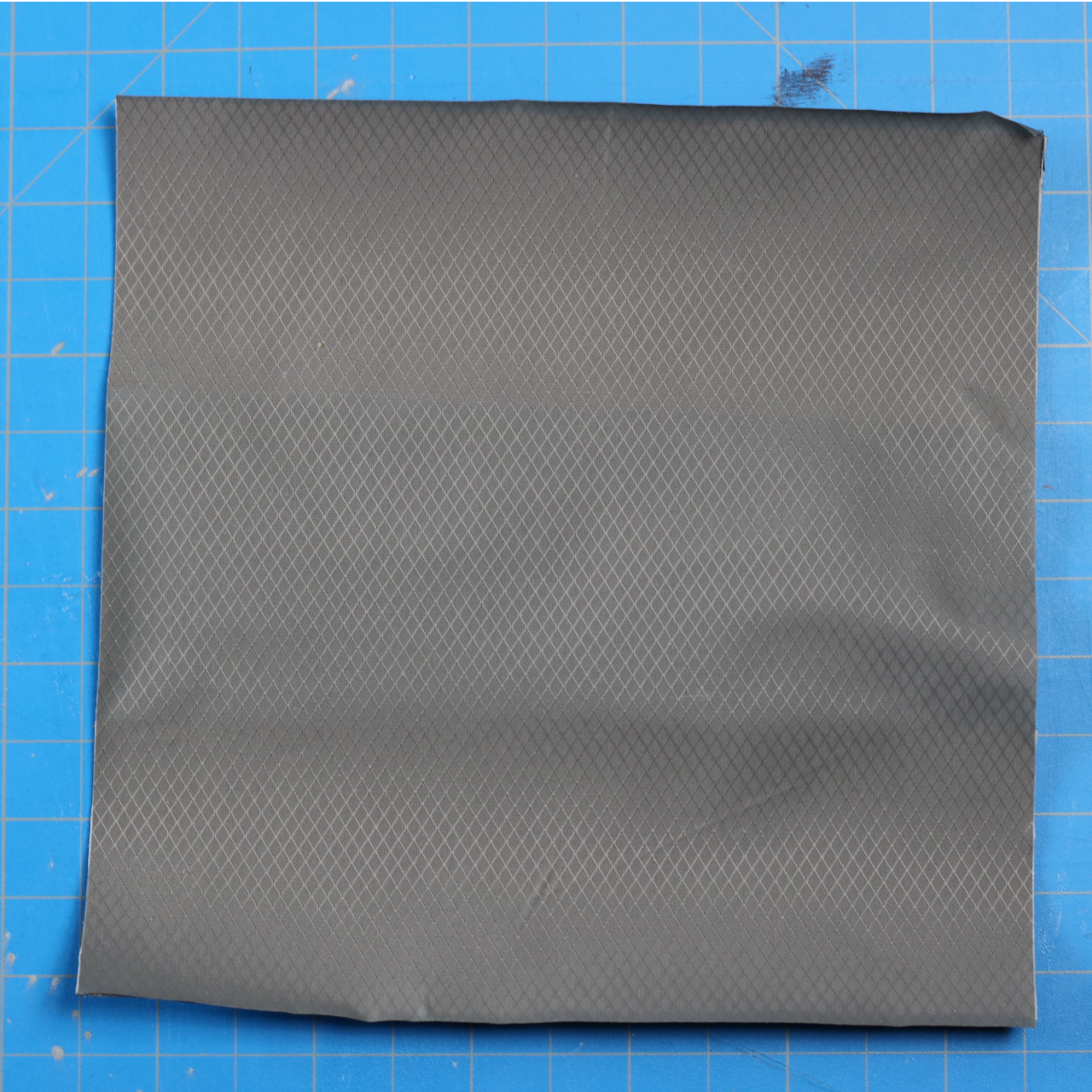

Waxed Canvas

This is waxed canvas, which has been treated with wax to help repel water. While it’s a great-looking and very durable material, it’s not ideal for beginners. Waxed canvas is usually quite heavy—this particular one is 21 ounces—and many home sewing machines struggle with fabric that thick.

Another thing to consider is that the wax coating wears over time, developing a patina that gives it character but can be unpredictable. Because waxed canvas creases easily, it’s usually shipped rolled, which adds to the cost.

Also, as you sew, some of the wax comes off onto your machine. You’ll need to clean it frequently to keep it running smoothly. Waxed canvas is a nice looking, but probably not the best choice for your first sewing project.

Synthetic Fabrics

Cordura

Cordura is a brand-name nylon fabric that’s commonly used for backpacks, laptop bags, and luggage. It’s extremely durable and often has a polyurethane coating on the back to improve water resistance.

Unlike cotton fabrics, Cordura is often described by denier, which refers to the thickness of the individual fibers. Higher denier fabrics are heavier, stronger, and more abrasion-resistant. For example, a 500-denier Cordura will feel lighter and more flexible than a 1000-denier version, which is thicker and stiffer

SilNylon

a lightweight synthetic fabric made from nylon that’s been coated with silicone for water resistance. It’s often used in applications like ultralight tents or stuff sacks. This particular sample has a ripstop weave for added strength and weighs just 1.6 ounces per square yard.

Compared to the other fabrics we've looked at, silnylon is much more flexible and slippery. It can be a bit tricky to sew, but it's ideal when you need a very lightweight, packable material.

Leather

Leather can be an excellent material for making a bag, but it comes with a few significant challenges. For that reason, I wouldn’t recommend using leather for your first project.

One of the main issues is cost. Leather is quite expensive. Unlike fabric, which comes in standard rolls, leather comes from animals, so it’s irregular in shape and size. When you buy leather, you’re usually purchasing a half or a quarter of a hide. Prices can vary widely, typically ranging from $100 to $300 or more, depending on the quality of the hide, the tanning process, and the type of animal it comes from.

Another thing to consider is that working with leather requires specialized tools and techniques that go beyond the scope of this course. Things like skiving, saddle stitching, edge finishing, and punching holes are all part of leathercraft, and they take practice to learn.

Leatherworking is a fun and rewarding hobby in its own right, and I highly encourage you to explore it further if you’re interested. But for the purposes of this course, we’ll be sticking to fabric-based projects.

Webbing

Webbing is a strong, woven material commonly used in bags where durability and strength are important. You’ll often see it used for straps, handles, or fastening systems. It typically comes in widths ranging from ½ inch to 2 inches, and the thickness can vary depending on its intended use.

Nylon Webbing

Nylon webbing is the most common and easiest to find. 1-inch-wide nylon webbing is especially popular and is commonly used for backpack straps, shoulder straps, or lid closures. Webbing is often paired with hardware like buckles and sliders. It's worth noting that most hardware is designed for 1-inch webbing, so finding parts for other widths can sometimes be more difficult.

MIL-W-5664: This is a military specification nylon webbing often used in backpack straps and tactical gear. It’s designed to meet certain strength and durability standards.

Cotton Webbing

Cotton webbing is another option and is typically used where high strength isn’t required. It’s much softer to the touch than nylon, but it can stretch or wear down over time. Cotton webbing works well for light-duty straps or decorative elements.

Here are a few examples of ½ inch, 1-inch, and 2-inch cotton webbing. As you'll see, the thickness can vary significantly even between webbing of the same width, so it's important to evaluate the webbing to your project’s needs.

Edge Binding

In bag construction, fabric edges can fray over time, especially on seams. To protect those raw edges and increase durability, we often use binding materials. These come in a few different forms, depending on the look and feel you’re going for.Grosgrain Ribbon

Grosgrain is a synthetic binding material that’s thin, flexible, and easy to sew. It’s a popular choice for edge binding because it can easily follow curved seams and holds up well over time. You’ll often find it used in commercial bags.

Herringbone Tape

Herringbone is a lightweight cotton option that’s also very flexible. Like grosgrain, its primary purpose is to protect fabric edges from fraying, and it’s especially good when you want a natural fiber option.

Bias Tape

Bias tape is created by cutting fabric strips on the bias, which means the threads run at a 45-degree angle to the tape's length. The edges are then rolled over to prevent the bias tape from fraying. This technique provides the tape with significant flexibility, making it ideal for binding around curves.

One benefit of bias tape is that you can create it from the same fabric used in your project, ensuring a perfect match. However, it demands a considerable amount of fabric due to the diagonal cuts. In most bag construction, this coordinated appearance isn’t essential, as the seams are typically concealed on the bag's interior.

Because of that, I recommend sticking to grosgrain or Herringbone tape is ideal for your binding needs in this course. It is easy to work with, readily available, and effective for protecting your seams.

Thread

Nylon Thread

For bag-making, nylon thread is commonly used—specifically Tex 70 bonded nylon. Tex 70 refers to the thread's weight and thickness and is known for its strength and durability. This makes it well-suited for seams that must withstand significant stress, which is essential in bag construction.

Tex 70 usually comes on a cone, which means you’ll need a thread stand to use it properly with most sewing machines.

Polyester Thread

Another popular option is polyester thread. This type of thread is generally lighter and thinner than nylon thread, making it more suitable for tasks such as hemming pants or sewing lightweight fabrics. While still strong, polyester thread is better suited for everyday clothing or detail-oriented work rather than heavy-duty bag construction.

Hardware

Pictured are several types of hardware used in the construction of a bag. The top tool is used for setting the button snaps shown in the left center of the picture. While button snaps are useful, they do require special tools to affix them to fabric.

The red coil shown is a #8 zipper purchased by the coil. The zipper is cut to length, and then the slider is attached before sewing it into the bag. Zippers can also be bought pre-made to specified lengths, which is the preferred method for beginner bag makers.

There is a wide variety of hardware available for use with webbing. The picture shows a small sample of what’s available, including slides used for adjusting loops of webbing, buckles for quickly disconnecting, and a J-hook, which can be used in place of a buckle in certain situations.