Joining Methods

Introduction

In this section, we will explore methods of joining fabric using various stitches, seams, and hems.

Hand sewing vs Machine sewing

Bags can be constructed using either hand sewing or a sewing machine. While many stitches are common to both methods, certain stitches, such as the hand-sewn backstitch, cannot be replicated by a machine. This course focuses on machine sewing; however, the project can be completed using hand sewing if preferred.

Stitches

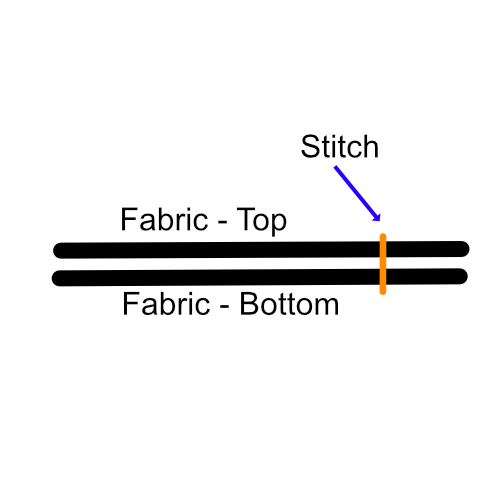

Straight Stitch (Image - right)

The straight stitch is the most fundamental stitch in sewing. Most household sewing machines create a lockstitch, where the needle thread interlocks with the bobbin thread beneath the fabric. This stitch is quick to produce and suitable for non-stretch fabrics. Adjust the stitch length based on the fabric's weave; finer fabrics typically require shorter stitches. Straight stitches are commonly used for seams, topstitching, and creating clean lines. To secure the seam and prevent unraveling, reverse stitch 2 to 6 stitches at the beginning and end.

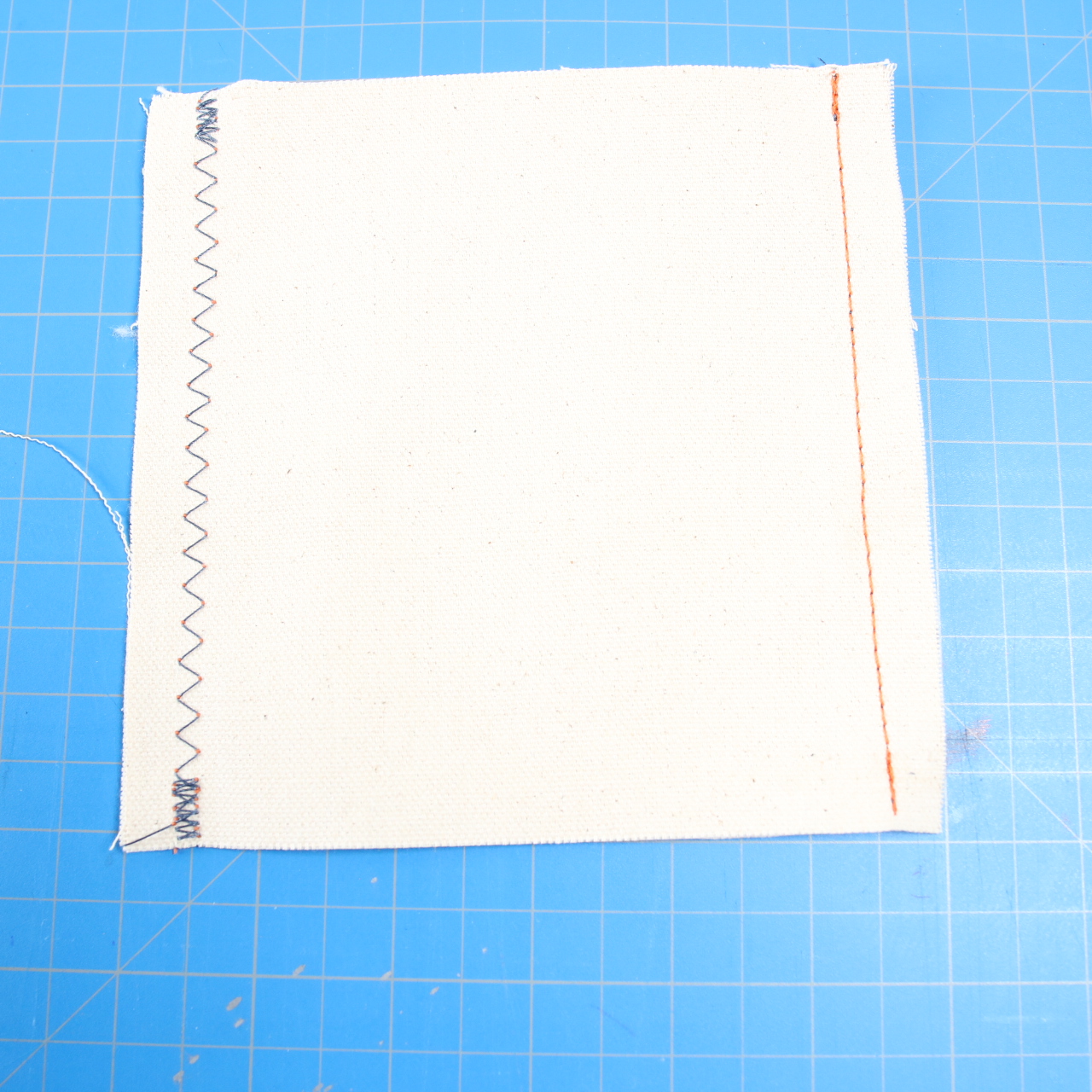

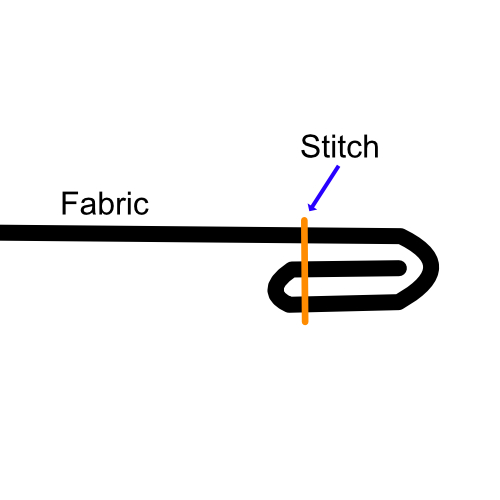

Zigzag Stitch (Image - left)

The zigzag stitch involves the needle moving side to side, creating a zigzag pattern. This stitch is ideal for stretchy fabrics or areas requiring high strength, as it distributes tension more evenly across the fabric. Additionally, zigzag stitches can be used to finish raw edges, preventing fraying.

Seams

Plain Seam

The plain seam is one of the most common seam types. It is created by placing two pieces of fabric right sides together and sewing through both layers. The seam allowance—the distance from the edge of the fabric to the stitching line—is typically on the inside of the project. Plain seams are versatile and can be used in various parts of a bag, such as attaching lid flaps or assembling the main compartment. To prevent fraying, consider finishing the seam allowance with methods like edge binding.

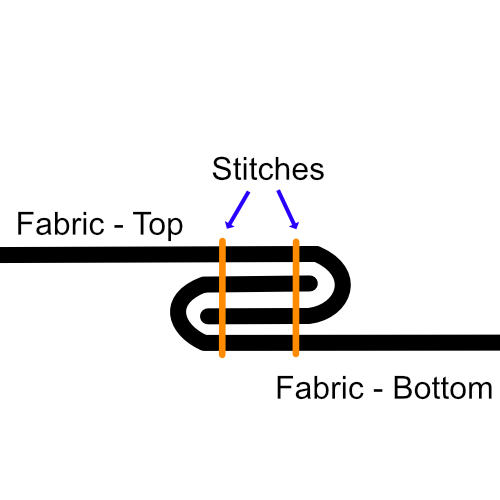

Flat Felled

Flat-felled seams are among the strongest seam types, commonly found in garments like jeans. They involve folding and enclosing raw edges, resulting in a durable and neat finish. Due to the multiple layers of fabric involved, sewing flat-felled seams can be challenging in tight or curved areas. Careful planning is essential to ensure accessibility during construction.

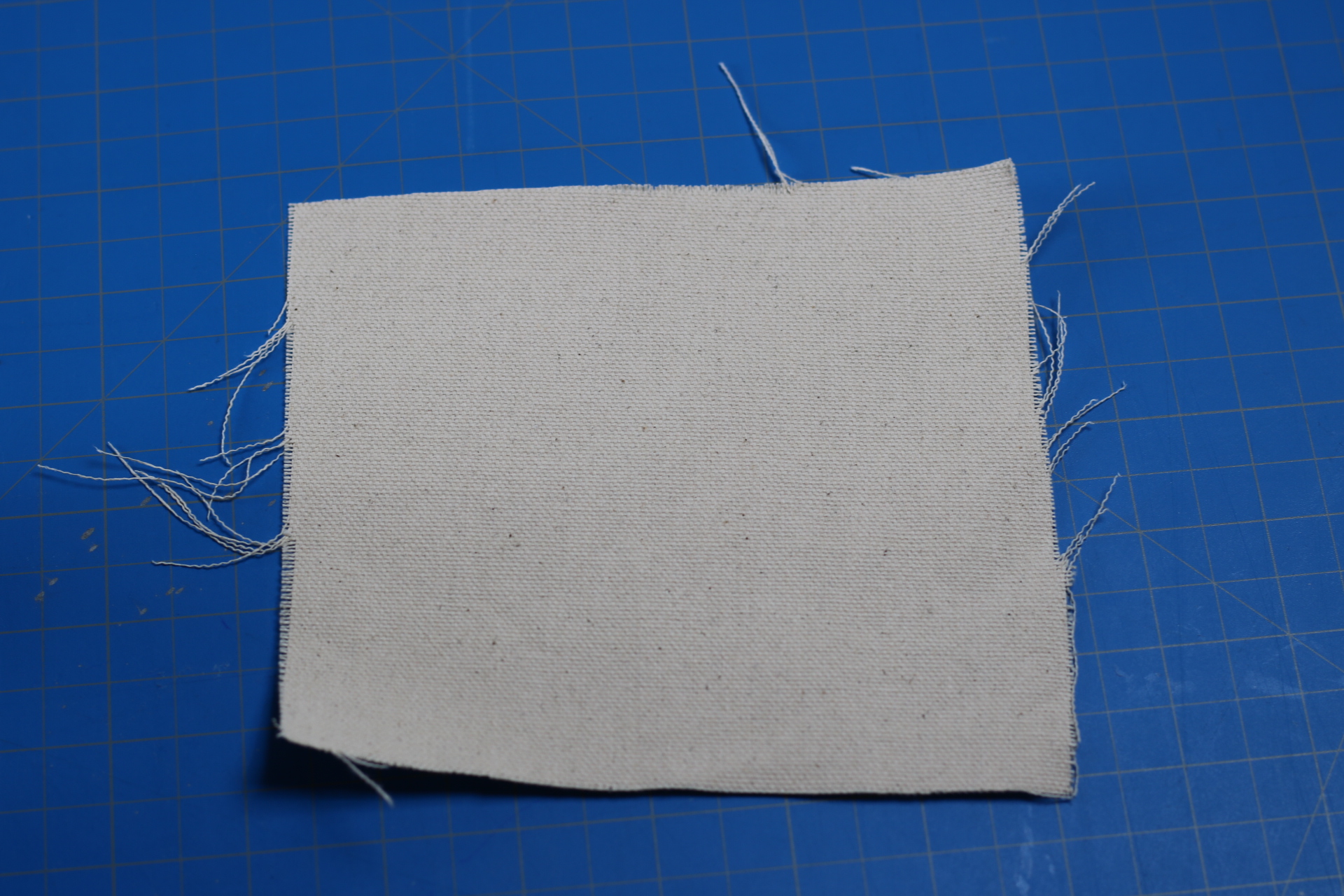

Hems

Hems are used to finish the edges of fabric, providing a clean appearance and preventing fraying. Properly executed hems contribute to the longevity and durability of the project.

Neglecting to finish fabric edges can lead to fraying, where threads unravel from the cut edge. This not only diminishes the aesthetic appeal of the item but also compromises its structural integrity over time. Frayed edges can catch on other objects, leading to further damage, and may result in seams weakening or coming apart entirely.

Rolled Hem

A rolled hem involves folding the fabric edge inward twice and stitching it down, commonly seen on pant legs. While this hem provides a clean finish, be cautious when working with thick fabrics, as multiple layers can be challenging for home sewing machine.

Edge Binding

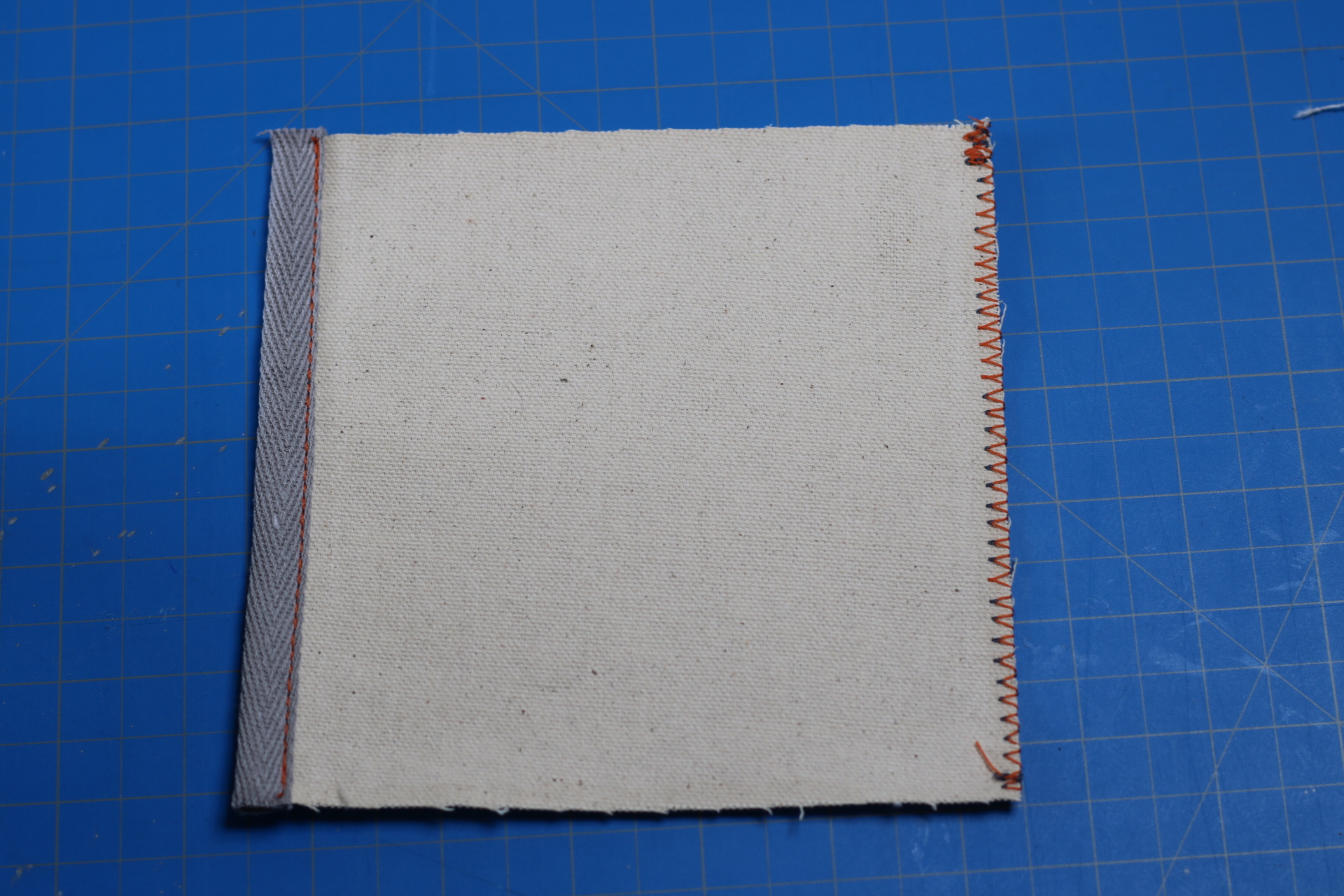

Overlock - Image Right

Overlocking, or serging, involves sewing over the edge of the fabric to prevent fraying. While specialized serger machines are commonly used for this purpose, a similar effect can be achieved on a standard sewing machine using a zigzag stitch that overhangs the fabric edge. Note that this method can be thread-intensive and may require practice to master.

Binding tape - Image Left

Edge binding is a method of finishing and protecting seam allowances by encasing them with binding materials such as grosgrain, herringbone tape, or bias tape. This technique is especially useful in bag construction, offering both durability and a polished look.

Webbing

When attaching webbing to fabric or other webbing pieces, reinforcement stitches are essential to ensure strength and durability.

Bar Tack

A bar tack is a series of closely spaced zigzag stitches used to reinforce areas subject to stress, such as where webbing is attached. To create a bar tack, set your machine to a narrow zigzag stitch with a short stitch length. Sew a short of stitches, then backstitch over the same area to secure. Bar tacks are commonly used in outdoor gear and apparel.

Box Stitch

The box stitch is used to attach webbing to fabric or other webbing pieces, providing a strong and secure connection. To create a box stitch, sew a square or rectangle, then stitch diagonally from corner to corner, forming an "X" inside the box. This method distributes stress evenly and is ideal for high-load areas.